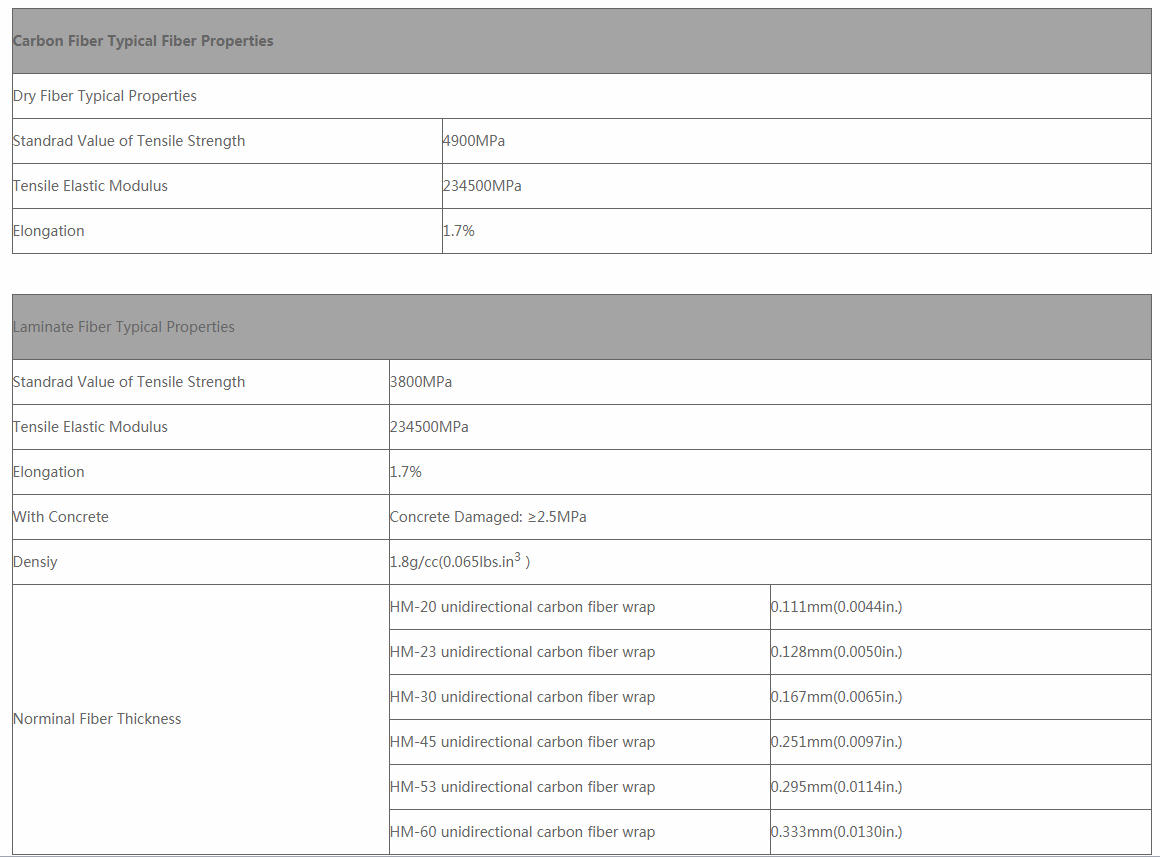

Carbon fiber reinforcement material characteristics

Carbon fiber reinforced plastics are made by combining carbon fiber materials with specific resin materials through a certain manufacturing process. Its mechanical characteristic is that the stress-strain variable is completely linear elastic, and there is no yield point or plastic zone. Carbon fiber materials have excellent physical and mechanical properties. The carbon fiber cloth used to strengthening reinforce concrete components is a soft sheet made of carbon fiber filaments by weaving. When carbon fiber cloth is woven, a large number of carbon fiber filaments are evenly laid out in one main direction. The main direction carbon fiber yarns are braided and connected together with very few non-main direction carbon fiber yarns to form a very thin carbon fiber cloth that is stressed in the main fiber direction. The standard value of the tensile strength of carbon fiber cloth should be greater than 3000Mpa, and the elastic modulus should be greater than 2.1105MPa. Comprehensive analysis of the physical and mechanical properties of the material, in order to maximize the advantages of the material itself, it is suitable to use CFRP material as the tension or pre-stressed bending member of the bridge structure, especially suitable for pure tension members. Engineering practice has also proved at this point. At present, the carbon fiber materials used for bridge reinforcement mainly bear tensile stress and restrain the development of cracks.

Key points of carbon fiber (sheet) strengthening reinforcement treatment

Before carrying out structural reinforcement treatment, first take effective measures to unload and support the beams and slabs, and then carry out reinforcement construction according to the following construction procedures.

1. Surface treatment of damaged concrete. Remove the degraded concrete such as peeling, looseness, honeycomb and corrosion on the surface of the reinforced component, and expose the concrete structure layer.

2. After treating the damaged surface steel bars according to the design requirements, use M45 epoxy mortar for grouting or sealing, and ensure that the thickness of the steel bar protection layer is not less than 15mm. Use a grinder to smooth the surface, and use a steel brush to remove dust, oil and other impurities on the surface to make the reinforced surface of the component smooth, dry and dust-free. In addition, if the carbon fiber needs to be pasted around the corner of the component in the direction of the base fiber, the corner pasting should be chamfered and polished into an arc shape, and the arc radius should not be less than 20mm.

3. Brush the bottom resin. Use a special roller brush to evenly smear the bottom layer resin on the concrete surface. When the resin surface is dry to the touch, proceed to the next process.

4. Leveling treatment. The concave part of the surface should be filled with leveling material and should not have edges or corners.

5. Paste the carbon fiber sheet. Spread the prepared impregnating resin evenly on the part to be pasted, and use a rubber roller to roll it along the fiber direction several times to squeeze out air bubbles so that the impregnating resin can fully penetrate the carbon fiber cloth without damaging the carbon fiber cloth during rolling. Repeat the above steps for multi-layer pasting. When the fiber surface is dry, the next layer can be pasted. If it exceeds 60 minutes, wait 12 hours before applying adhesive to paste the next layer.

6. Spread the impregnating resin evenly on the surface of the last layer of carbon fiber cloth.

7. If necessary, carry out surface protection and appearance treatment.

Precautions for carbon fiber strengthening reinforcement

1) Matters needing attention in the selection of carbon fiber sheet

The weaving uniformity of the carbon fiber sheet will directly affect the reinforcement quality. Only when the carbon fiber bundles are evenly distributed and arranged and processed into composite materials can they exert a uniform force on the whole. If the uniformity of the material is not good, the fiber sheet after the component is stressed will not be uneven, so that the effect of carbon fiber reinforcement cannot be fully exerted. Therefore, choosing a carbon fiber sheet with better uniformity is the key to the quality of strengthening reinforcement.

2) Matters needing attention for carbon fiber (sheet) strengthening reinforcement

①Before surface treatment and pasting of carbon fiber sheet, the line should be positioned according to the reinforced design position.

② Cut the carbon fiber sheet according to the size required by the design. The width of the cut fabric should not be less than 150mm and should not be less than 100mm.

③Wipe the surface of the carbon fiber sheet clean to no dust. When two layers need to be pasted, both sides of the bottom carbon fiber sheet should be wiped clean.

④The cleaned carbon fiber sheet should be coated with bonding resin immediately, and the glue layer should be convex, with an average thickness of not less than 2mm.

⑤Apply the carbon fiber sheet coated with bonding resin to the position to be pasted by hand. Use a rubber roller to compact evenly and smoothly along the direction of the fiber sheet, so that the resin overflows from both sides, ensuring compactness and no voids. When the carbon fiber is pasted in parallel, the gap between the two sheets should not be less than 5mm. .

⑥ When two layers of carbon fiber sheets need to be pasted, they can be pasted continuously. If it cannot be pasted continuously, clean the bottom carbon fiber sheet before starting again.

⑦The construction should be carried out at an ambient temperature of 5℃ or higher, and should comply with the construction use temperature of the supporting resin. When the ambient temperature is lower than 5°C, a supporting resin suitable for low temperature should be used or heating treatment measures should be adopted.

⑧ The adverse effect of environmental humidity on resin curing should be considered during construction, and the moisture content of the concrete at the sticking position should not be greater than 4%.

⑨When preparing the resin, it should be weighed and placed in a container according to the proportion specified in the product instructions, and stirred with a stirrer until the color is uniform. There must be no oil and impurities in the mixing container. It is advisable to determine the mixing amount of the resin each time according to the actual temperature on site, and strictly control the use time.

⑩In order to ensure the quality of the paste, different types of paste resins should be used in different seasons and different temperature conditions, so that the operating time and curing time of the resin construction can be effectively controlled.