Bridge Overview

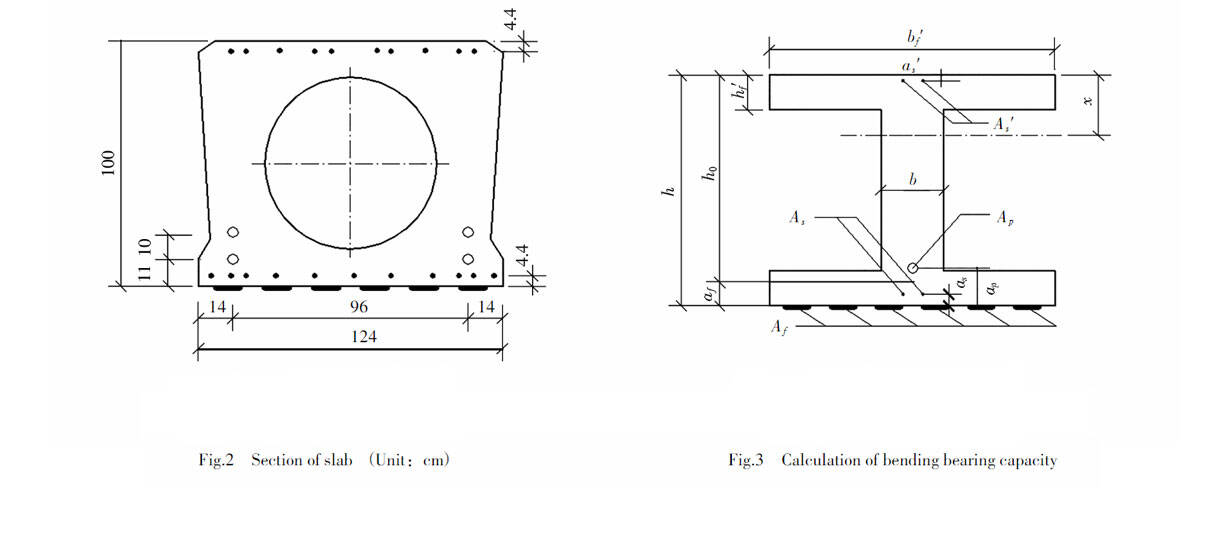

A bridge was built in 1998. The original design load is automobile-over 20 tons, trailer -120 tons, simple support structure. The standard span of the bridge superstructure is 20m and 25m, the beam height is 0.9m and 1.0m respectively, with a total of 78 holes, and the total length of the bridge is 1951.6m. The whole bridge is divided into two, the two bridges have the same layout, and the total bridge has a total of 982 hollow slabs. The width of the middle plate is 1.24m and the width of the side plate is 1.64m. The post-tensioned partial prestressed concrete members of Class A are originally designed with concrete strength grade 40, the standard strength of prestressed steel strands is 1860 MPa, and the ordinary steel bars are HRB335 steel bars.

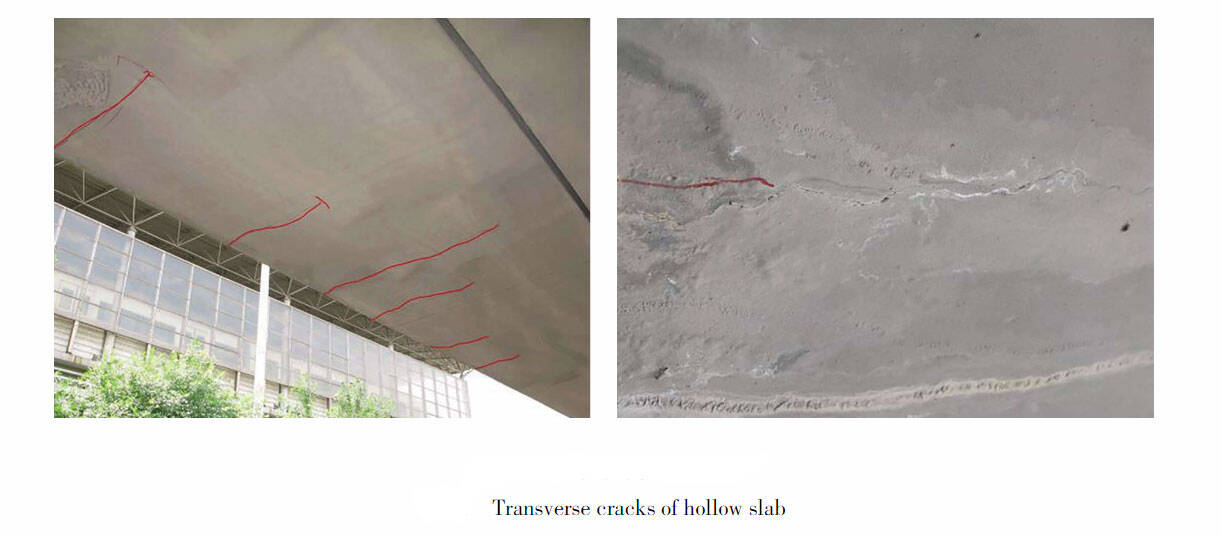

Bridge disease

Inspection of 982 post-tensioned prestressed hollow slabs of the full bridge revealed that there were transverse cracks at the bottom of 138 hollow slabs (see Figure 1), accounting for 14.05% of the total number of hollow slabs. The cracks are distributed within 5 m from the mid-span cross section, and are mostly located at the location of the transverse stirrups of the bottom plate, with a spacing of 0.2-3 m and a crack width of 0.02-0.22 mm. Among them, the cracks with a width of 0.02-0.10 mm account for more than 90% of the total, the crack depth is 20 mm-34 mm (the thickness of the protective layer is 35 mm), the cracks extend along the beam height to the web 0.4 y 0.6 m, and some cracks penetrate the bottom plate to form a U shape crack.

According to the inspection results of cracks, the width of the cracks has not met the requirements of the regulations, the actual bearing capacity of the prestressed hollow slab structure has significantly decreased compared with the design bearing capacity, so the prestressed slab beam should be replaced or repaired and strengthened

Bridge strengthening

Consider factors such as construction period, construction cost, the impact of structural diseases, material degradation, and whether new and old materials can be effectively bonded and coordinated after reinforcement. After comparison and selection of the scheme, 15 slab beams with dense cracks at the bottom of the beam and severe deflection were replaced with the main beam. The main beams with transverse cracks at the bottom of the remaining beams are reinforced with non-prestressed carbon fiber plates to improve the bearing capacity of the structure.

Paste a layer of 100mm wide and 1.4mm thick carbon fiber plate to the bottom of the beam.

Strengthening beam bridge with carbon fiber plates

After the carbon fiber plate is used to reinforce the slab beam, the deformation and strain of the bridge meet the design load standard requirements, and the flexural bearing capacity of the bridge is improved after the reinforcement. Since the bridge was reinforced and opened to traffic two years ago, no new disease has appeared on the bridge, and cracks at the bottom of the beam have not expanded. Therefore, the reinforcement method of pasting carbon fiber sheet has a good inhibitory effect on the development of existing cracks and the generation of new cracks. On the basis of reasonable economy and simple construction, the use of carbon fiber sheet to strengthen the bridge can meet the operational requirements, and the bridge is in safe use.

No comments:

Post a Comment