Carbon fiber reinforced polymer

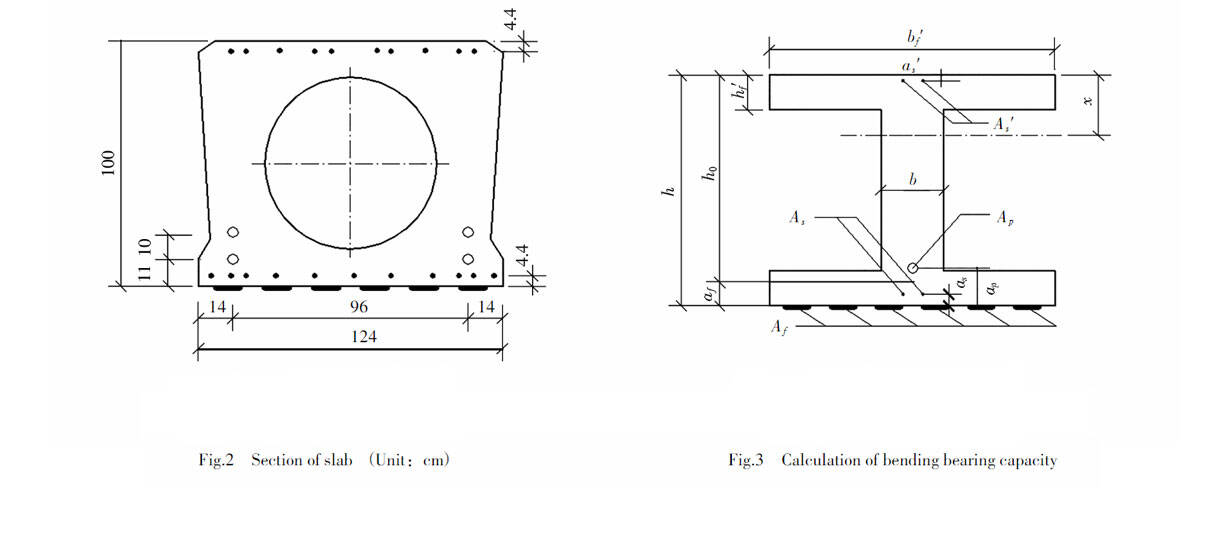

Carbon fiber structure reinforcement technology refers to the use of high-performance adhesives to paste carbon fiber wrap on the surface of building structural members, so that the two work together. Improve the load-bearing capacity of components (bending, shearing), so as to achieve the purpose of strengthening the building. Carbon Fiber Reinforced Polymer (CFRP), also known as Carbon Fiber Reinforced Plastic, is made of epoxy resin with high tensile strength carbon fiber bundles. Carbon fiber wrap is a widely used product.

The use of carbon fiber wrap reinforcement has the following advantages: high strength and good effect. After reinforcement, the corrosion resistance and durability of the structure are greatly improved. Light weight, basically does not increase the structure weight and cross-sectional size. Good flexibility, easy to cut, wide range of application; convenient construction, easy to operate, and good economy. The construction period is short.

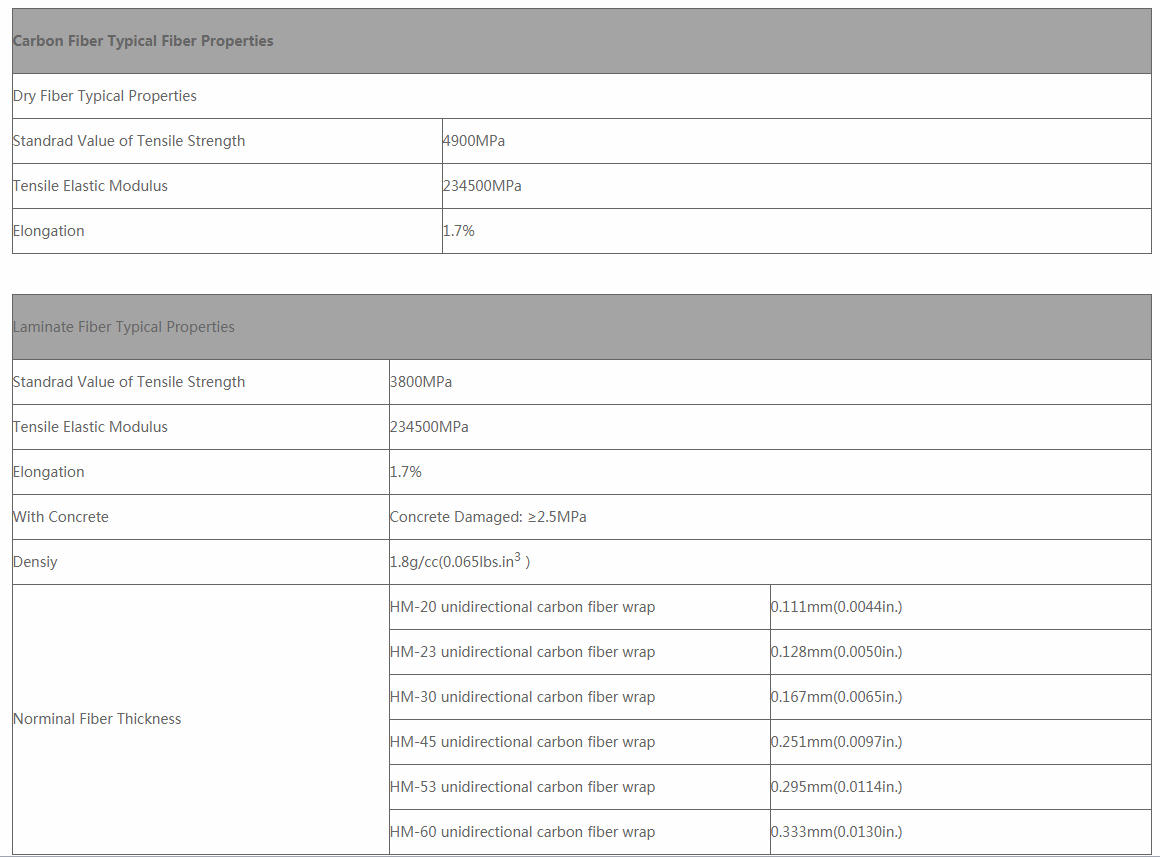

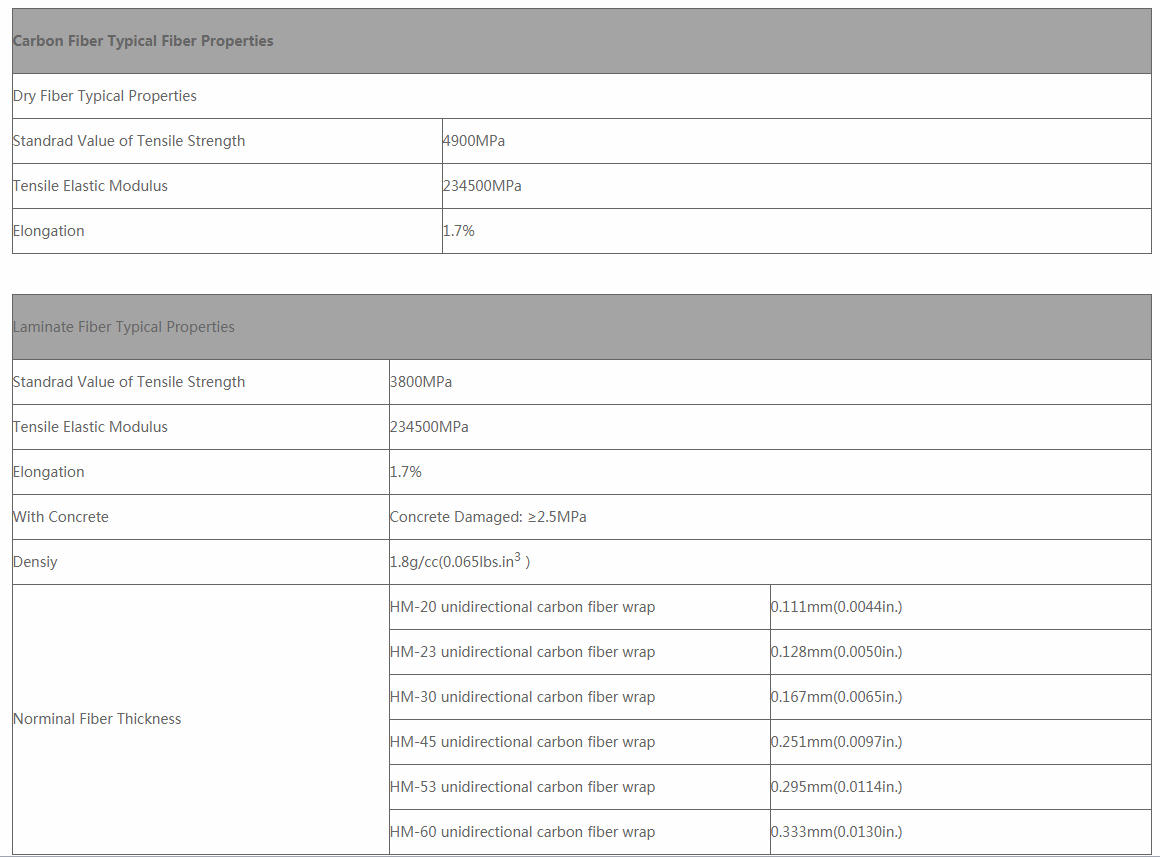

The main performance indexes of carbon fiber wrap for structural reinforcement are shown in the table

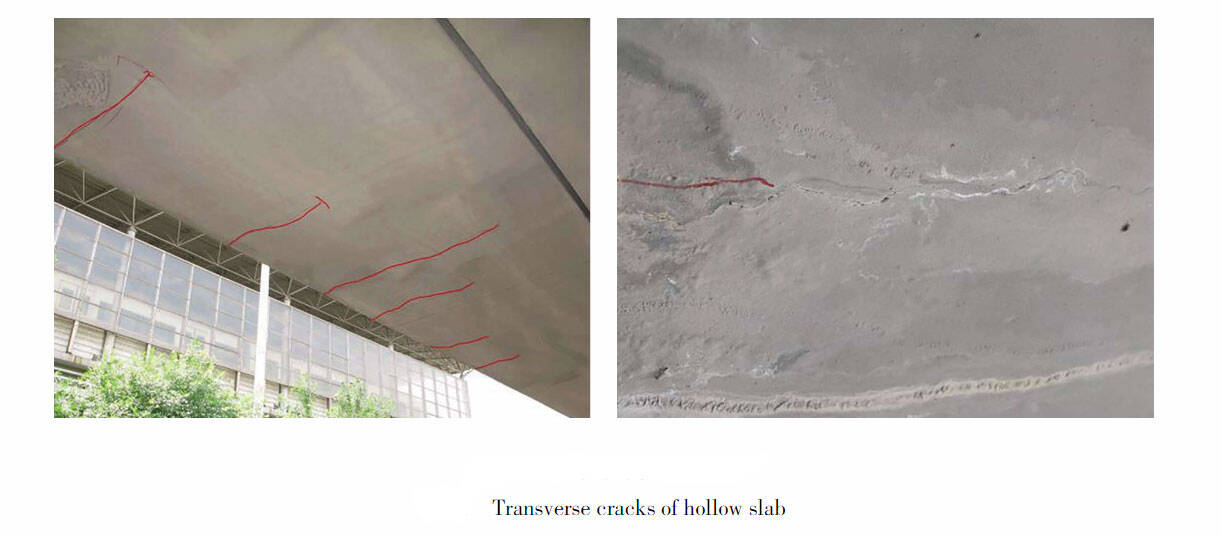

The durability of reinforced concrete with carbon fiber

After the introduction of carbon fiber wrap reinforcement technology in my country, its application in civil construction structures, especially the reinforcement and repair of concrete structures, has developed rapidly. Moreover, the durability of concrete structures reinforced with carbon fiber wrap has attracted more and more attention. The carbon fiber wrap reinforcement method adopts a specific method to arrange continuous carbon fibers unidirectionally to form a reinforcing reinforcement material, and uses a two-component epoxy resin to adhere to the outer surface of the treated structural member to improve the structural function.

At present, the construction of carbon fiber reinforced and repaired concrete structures applied in China basically adopts a three-step method, that is, on the basis of the base treatment, the base resin with different properties and functions, the leveling material, and the impregnating resin are used to paste the carbon fiber wrap on the surface of the concrete. After the resin is cured, it can improve the load-bearing capacity of the component, improve the form of stress, improve the performance or anti-corrosion. Based on this construction method, the bonding interface performance of various materials is crucial. The durability of the reinforced concrete structure with carbon fiber wrap mainly depends on the durability of the carbon fiber wrap material and the durability of the bonding interface with the concrete.

Carbon fiber reinforced steel structure

The commonly used steel structure reinforcement method is to add welded steel and steel plates. This method will increase the size of the structure to a certain extent, resulting in an increase in the weight of the structure and a change in rigidity, resulting in the redistribution of the internal force of the structure. And in the construction, we must rely on mechanical equipment, especially when working at heights, with certain difficulty and danger. The carbon fiber wrap is used for reinforcement and reinforcement, which can be done manually, and has good corrosion resistance, and there will be no corrosion after steel plate reinforcement.

Carbon fiber reinforced masonry structure

Brick-concrete structure is widely used in my country. Reinforcement and restoration of existing brick-concrete buildings is a hot issue generally concerned by the construction engineering community. The use of carbon fiber wrap to reinforce and repair brick masonry is still in the initial stage of experimental research internationally, and the research on this technology in China is still blank. Carbon fiber wrap reinforced masonry structure technology has the advantages of not increasing the weight and volume of the components, high strength and efficiency, convenient construction, good corrosion resistance and durability, and wide application range, and has broad application prospects.

Carbon fiber wrap is a very effective reinforcement method for enhancing the seismic resistance of brick masonry structures. The cracking load (limit load) of the carbon fiber reinforced wall is significantly higher than that of the unreinforced wall.

When carbon fiber wrap is used to reinforce brick walls, the larger the width of the wrap, the more obvious the reinforcement effect. The carbon fiber wrap improves the stress state in the wall through the tension bar mechanism in the truss model, thereby improving the shear capacity of the member. In addition, by restricting the development of cracks in the wall, the crack resistance of the component is also improved. Carbon fiber wrap is used to reinforce the brick masonry structure, and the reinforcement at both ends of the fiber wrap is very important. Because when the bond between the fiber wrap and the masonry breaks, the energy is suddenly released and severe brittle failure occurs, so ductile anchoring at both ends of the carbon fiber wrap is required. Carbon fiber wrap can be used not only to reinforce and repair the existing brick-concrete structure, but also to reinforce concrete small hollow block walls.

Conclusion

Carbon fiber wrap has good performance in the reinforcement and repair of various structures, and has good durability. It can solve the reinforcement and repair problems of many special projects and has great application potential. Although the cost is high at this stage, with the further research on the performance and construction technology of carbon fiber wrap, and the development of production technology, the carbon fiber wrap reinforcement and repair technology will be more and more widely used.